Product introduction

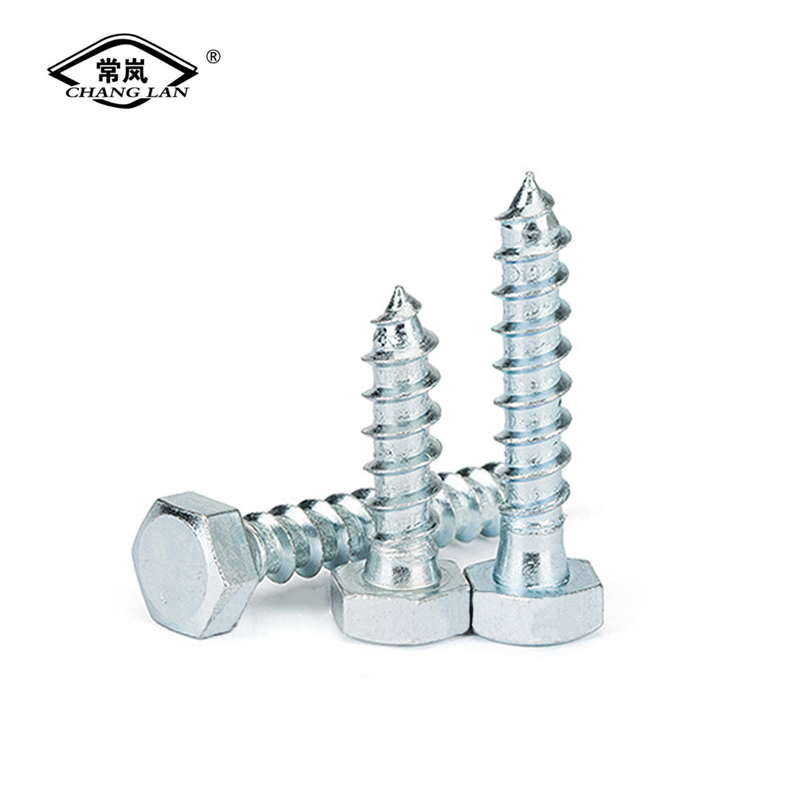

Self tapping screw is a kind of screw with drill bit, through the construction of special power tools, drilling, tapping, fixing, locking completed at a time. Self tapping screws are mainly used for connection and fixation of some thin plate parts, such as color steel plate and color steel plate connection, color steel plate and purlin, wall beam connection, etc

Self tapping screw hardness is high, thread spacing is wide, thread depth, the surface is not smooth, wood screw is on the contrary, another difference is more obvious, wood screw after the segment without thread. Wood screw thread thin, blunt and soft point. Tapping screw threads are thick, sharp and hard.

Thread Forming self-tapping Screws are directly developed from iron Screws. Before using screw Forming self-tapping Screws, holes should be drilled in advance, and then Screws are screwed into the holes and forcefully extruded to match the female threads. The materials originally in the position of the female threads will be squeezed between the male threads. Can only be applied to thin and plastic materials, so also developed; Thread Cutting Tapping Screws -- One or more Cutting openings are cut at the end of the threads so that the mating negative threads can be cut using screw tails and teeth in a screw Tapping manner when screwing the pre-holes. It can be used in thick plates, relatively hard or fragile materials that are not easy to shape.

About Us

Handan Chang Lan Fastener Manufacturing Co., Ltd. formerly Yongnian Tiexi Changhe fastener factory was large-scale standard fastener manufacturer in Yongnian District. The company is located in standard fastener distribution center of Hebei Yongnian, covering an area of 3,050 square meters, was close to Tianjin Port and Qingdao ports, export is very convinedtly. The company has multi position cold heading machine, model 12b, 14b, 16b, 24b, 30b, 33b; has hot forging machine, model has 200 tons, 280 tons, 500 tons, 800 tons;

Has a variety of supporting equipment, including rolling machine, rolling machine, oil press, etc. for bolts, nuts, double stud bolts , foundation bolts and complete product testing equipment. With an experienced technical research and development team, high-quality management personnel and spacious production environment.

Product attributes

| Product name | Tapping Screw |

| Brand | CL |

| Product model | M6-200 |

| Surface treatment | Black、galvanized、Hot dip galvanized |

| Material | Carbon steel |

| Standard | DIN、GB |

| About the material | Our company can customize other different materials different specifications can be customized |